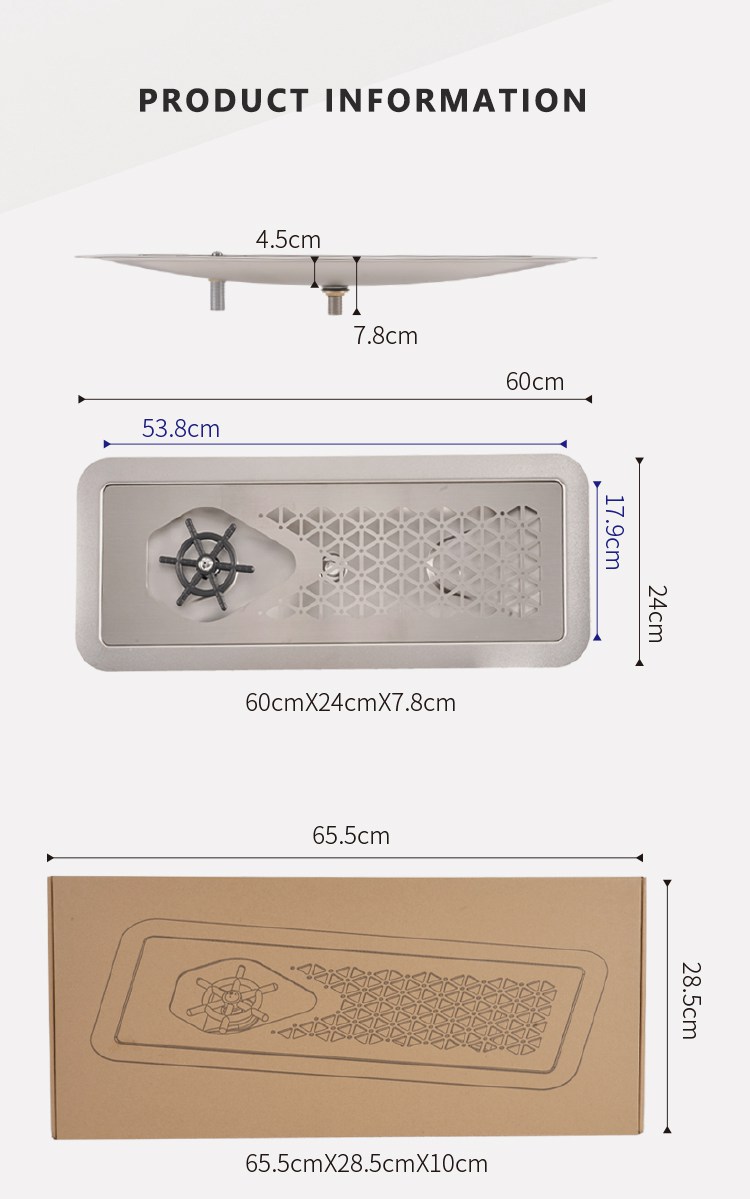

The Bar And Cafe Rinser is a built-in bar counter/coffee cup rinser. Its panel measures 600 × 240 × 78 mm and fits directly into a 538 × 179 mm opening. The outer flange is approximately 45 mm high. The tray and cover are extruded from SUS304 stainless steel. The spray head and base are made of ABS engineering plastic. The nozzle is located on the left side, with a large quick-discharge grille on the right. Pressing the nozzle downward on the cup rim triggers a 360° water jet rinse.

Place of Origin: China

Logo: Accept Customized Logo

OEM/ODM: Availalbe

Material:stainless steel 304+ABS

Size:as pictures

Color:sliver

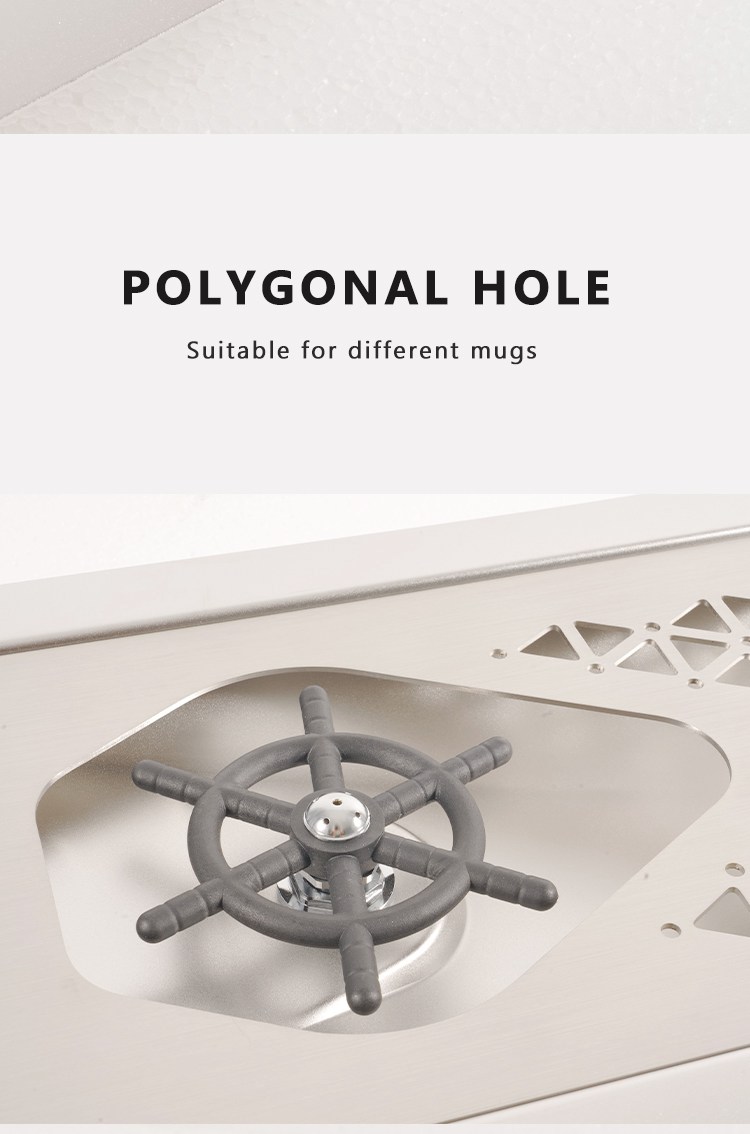

The nozzle features a radial multi-porous structure. When used with a standard water supply of 0.2–0.4 MPa, the water jet creates a 360° coverage of the cup wall, rinsing away milk stains and coffee oils in just 2–5 seconds. It also operates stably within a wider water pressure range of 0.1–0.6 MPa. The nozzle is removable and cleanable by hand, and features internal anti-clogging ribs to prevent water loss even with prolonged pressure. The recommended operating water temperature is 4–60°C, making it suitable for daily hot and cold cleaning in coffee bars and milk tea shops.

The water-receiving surface and flow path are made of 304 stainless steel, resistant to rust even with long-term contact with dairy products and coffee detergents. All seals are made of food-grade silicone, ensuring leak-free operation despite repeated hot and cold cycles. The ABS nozzle is impact-resistant and scale-resistant, and the compression seal between the nozzle base and the panel allows for easy disassembly and maintenance without damaging the panel finish.

The unit is simply inserted into the 538×179 mm opening. The large 600×240 mm panel naturally covers the cutout, with a 45 mm flange for water protection, making it compatible with both bare countertops and stainless steel sinks. A G1/2" inlet is reserved at the bottom, allowing direct drainage to a regular basin drain. From drilling to installation and pipe connection, the entire process takes approximately 10-15 minutes.

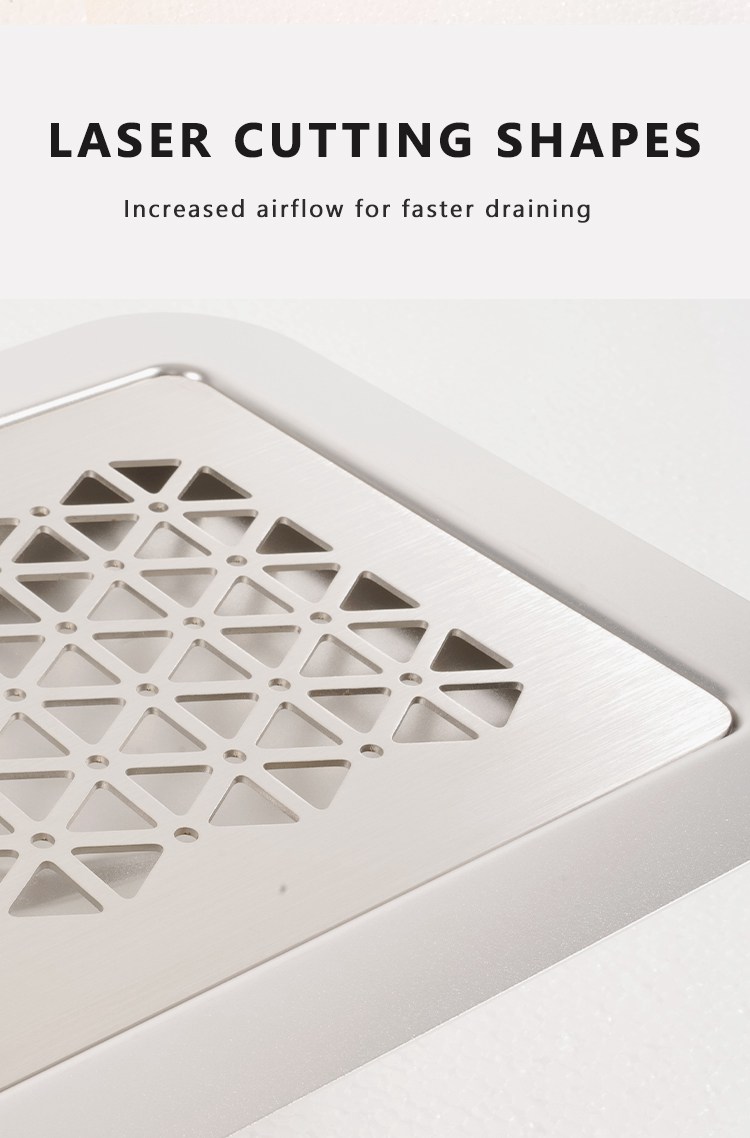

The interior of the tray features a 2% slope, which, combined with the large diamond-shaped grille on the right side, creates a "fast in, fast out" flow path. Even during peak hours of continuous flushing, 78 The 100mm cavity height and drain outlet keep the surface dry. The grille can be fully retracted, and the sediment area collects coffee grounds, fruit pulp, and milk skin, allowing for easy disposal and wiping.

All contact surfaces have blunt corners that prevent scratching. The brushed stainless steel cleans easily with a single wipe. The ABS nozzle and grille are tool-free to install and disassemble. Daily cleaning requires warm water and a neutral cleaner, while weekly cleaning can be performed by soaking the entire unit for descaling. The panel's four edges are flanged and finished in silver, matching the bar's style. Once installed, it sits flush against the countertop, preventing warping and preventing snagging on stations and carts.

We support laser/silk-screen printing of logos, custom panel dimensions, number of nozzles, hole positions, and water inlet connections. We also provide OEM/ODM proofing and installation templates according to chain store SOPs, facilitating rapid, large-scale project implementation.

Bar and Cafe The Rinser is installed between the grinder and espresso machine. After extracting the milk frother, press down for 2–5 seconds to remove milk stains. With your other hand, you can simultaneously clean the steam wand and remove cups. The 600×240 mm panel provides minimal depth, and the 360° spray coverage covers the bottom and sides of the cups, ensuring smooth operation during peak hours.

The cold counter features a 538×179 mm drop-in hole on the operator's side, allowing for quick rinsing of the threaded openings of shakers and measuring cups. A 0.2–0.4 MPa water supply creates a powerful water curtain, while a large grille on the right side traps fruit pulp and tea residue, preventing them from entering the drain and causing subsequent blockage.

The Bar And Cafe Rinser is located next to the beer tap. Pressing the cup mouth against the ABS nozzle pre-chills and removes foam stains. The 304 panel is resistant to beer acid residue and cleaning chemicals. Simply remove the grille for rinsing after closing. The 78 mm cavity height prevents stains and allows for immediate use the next day.

The Bar And Cafe Rinser is located next to the beer tap. The rinser is built into the juice/coffee self-service island, featuring a 45mm flange that reduces splashing and keeps floors dry. Employees on different shifts simply remove the nozzle and grille for cleaning and resetting according to daily/weekly cleaning procedures, making maintenance and inspection simple and reproducible.

The Bar and Cafe rinser is installed alongside the water heater to the right of the sink. A G1/2" hose connects directly to the property water supply. It reliably rinses mugs and thermoses at common water temperatures of 4–60°C. Weekly inspections by the administration staff complete maintenance by replacing the seal and recording the descaling date.